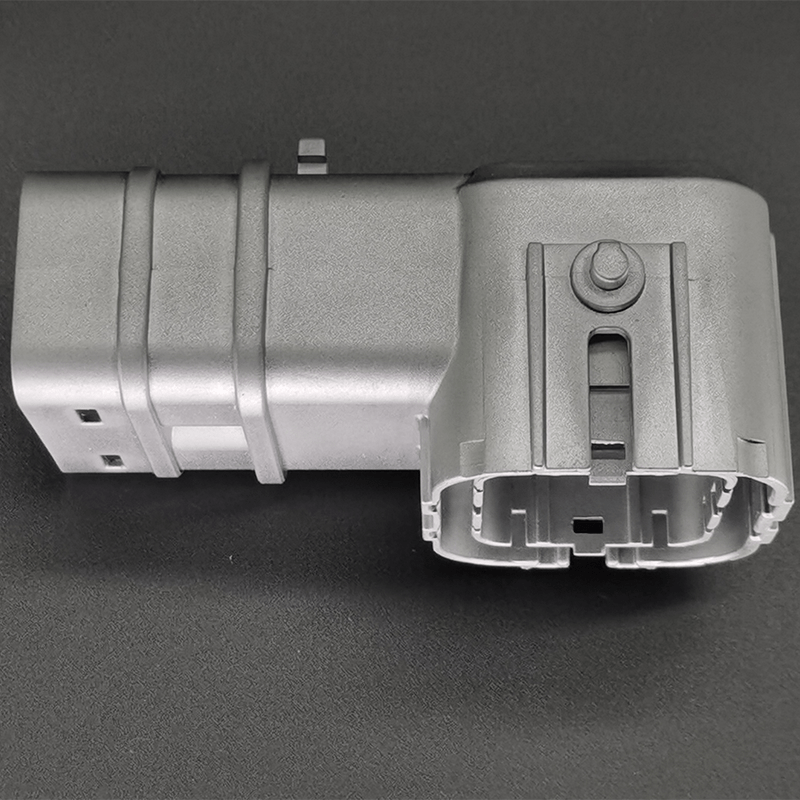

Inverter zinc alloy die casting:

Inverter zinc alloy die-casting parts are widely used in air conditioners, home theaters, electric grinding wheels, and power tools.

1.Inverter zinc alloy die casting Product introduction:

Zinc alloy die-casting inverter inverter is a converter that converts DC electric energy (battery, storage battery) into constant frequency and constant voltage or frequency and voltage regulation AC. The raw material is ZA-8.

2. Inverter zinc alloy die casting product specifications:

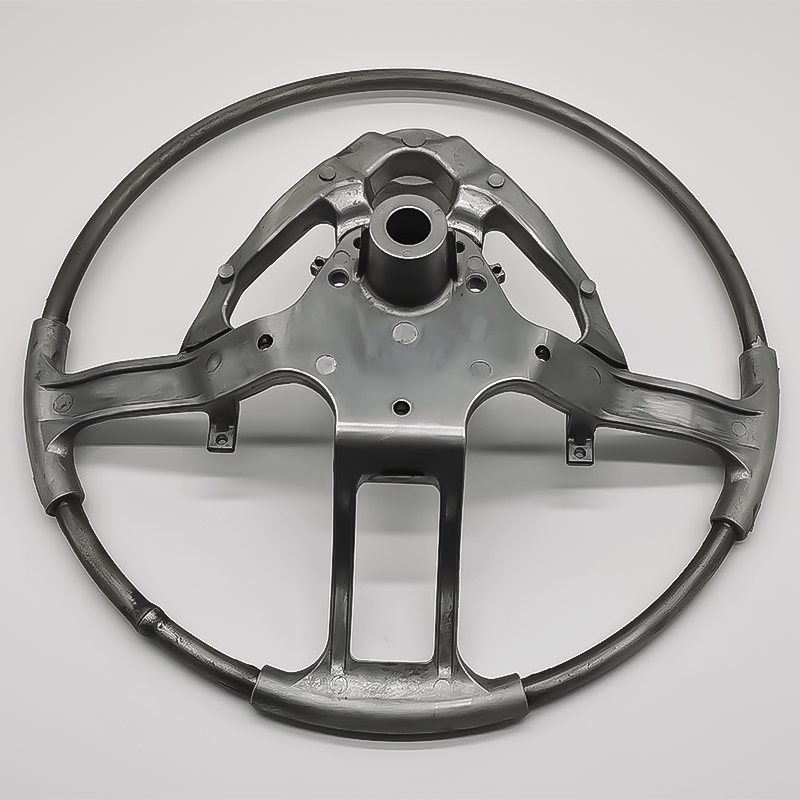

| product name | Steering wheel aluminum alloy die casting |

|

Product Weight |

1200g |

| Product Cavity | 1 Cavity |

| Product Material | ADC12 |

| Product Size | 397x401x127m |

| Die casting machine model | 650T-800T |

| Die casting machine model | 650T-800T |

|

Mold specifications |

DME, HASCO, LKM, MISUMI, CUMSA or the requirements you provide |

| Die casting material |

commonly used materials : aluminium alloy:ADC12,A380,ADC1,A356 magnesium alloy :AM50,AM60,AZ91D zinc alloy:Z3,ZA-8,ZA-12,ZA-27 |

| Machine center | drilling machines and other mechanical spark machines, milling machines, punching machines, tapping machines,polishing machines, engraving machines, cranes, mold supporting machines, automatic polishing machines, die-casting machines, etc. |

| Mold manufacturing process |

1. DFM and mold design 2. Project Management Process 3. Mold manufacturing 4. Quality Control 5. Die Casting 6. Assembly and secondary operation 7. After-sales |

3. FQA:

Q: Are you a trading company or a manufacturer?

A:YuanZhang Mold is a Die casting mold manufacturer with 15 years of experience.

Q:How long is your delivery time?

A:It usually takes 25-30 days if the final design drawing is finalized. For complicated moulds, we will reply to you according to the specific situation.

Q:Do you provide samples? Is it free or extra?

A:Yes, we can provide samples for each test for free, but no shipping fee.

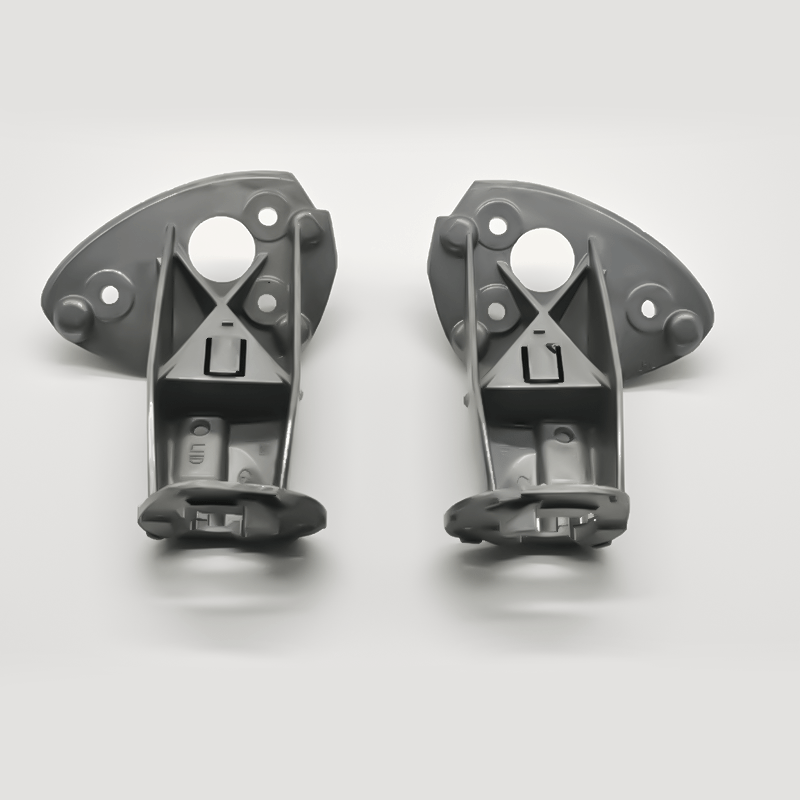

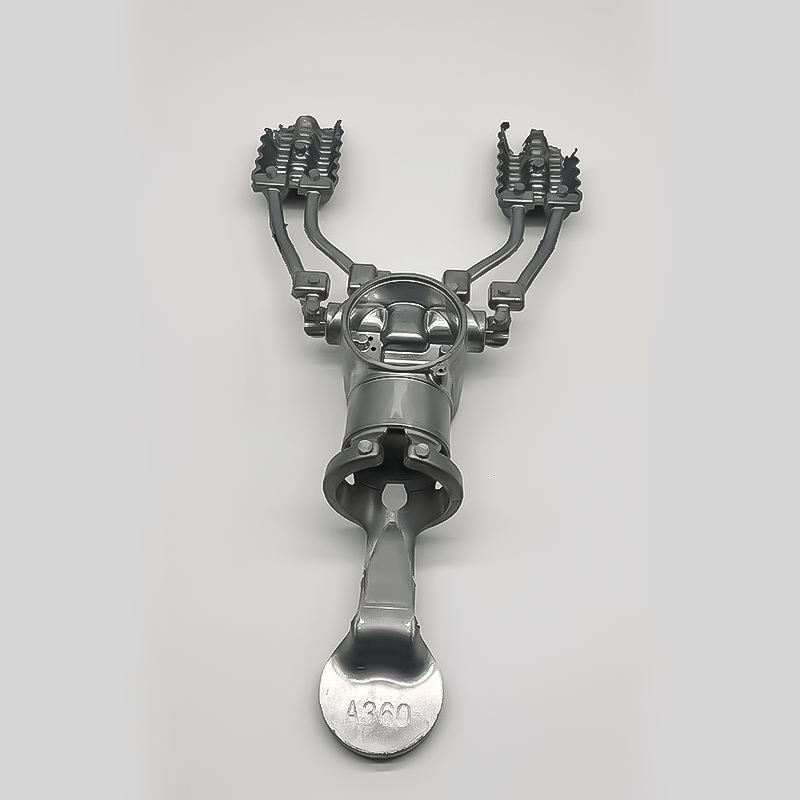

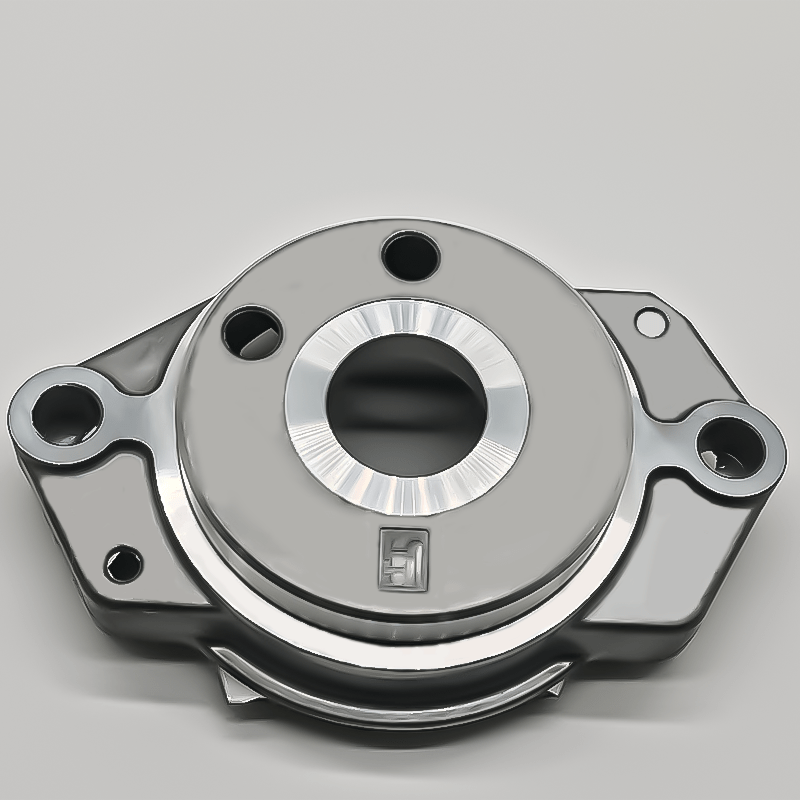

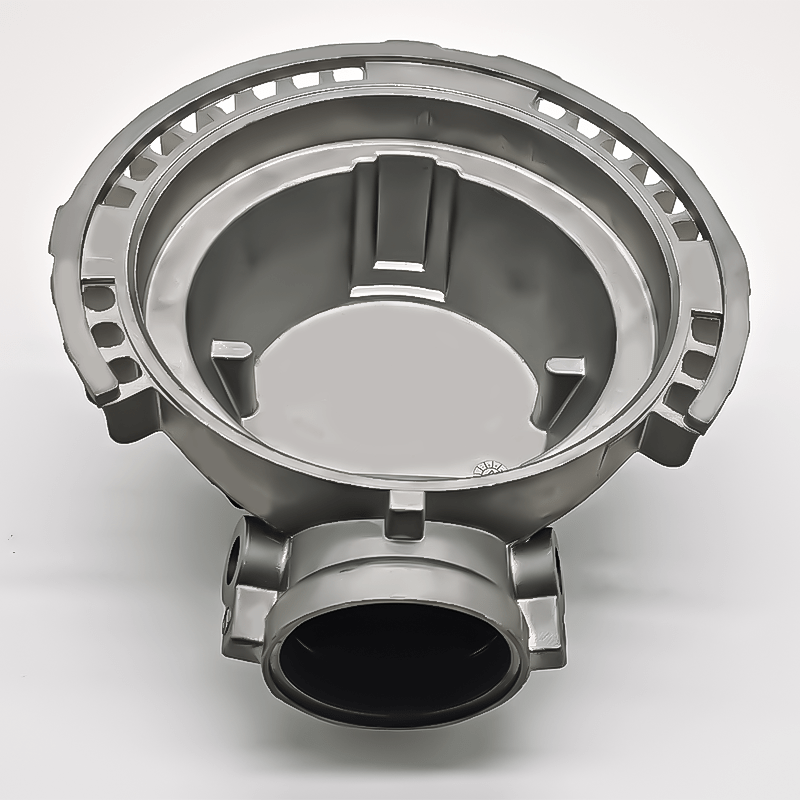

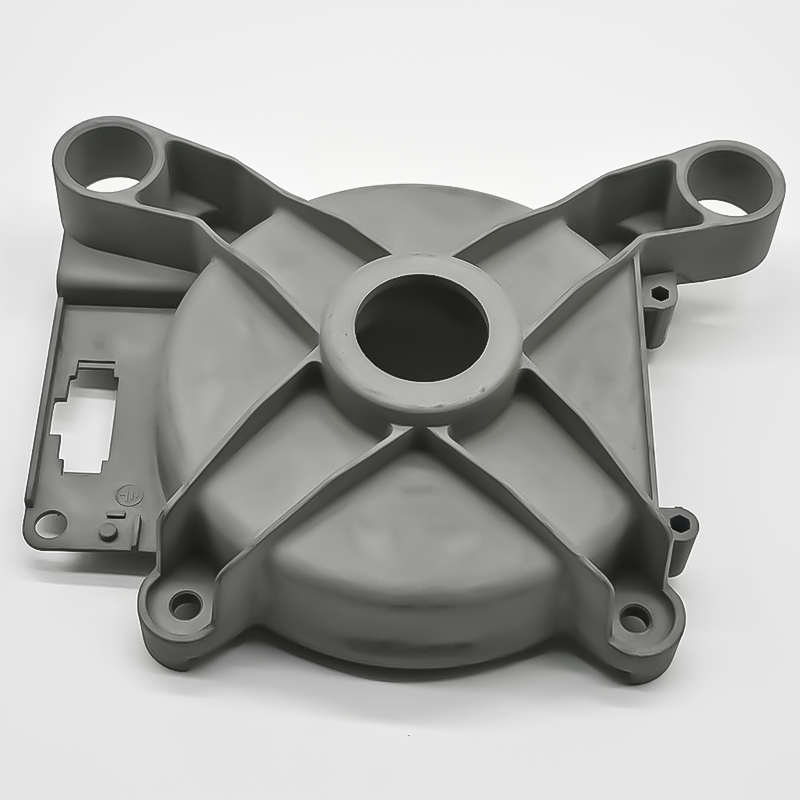

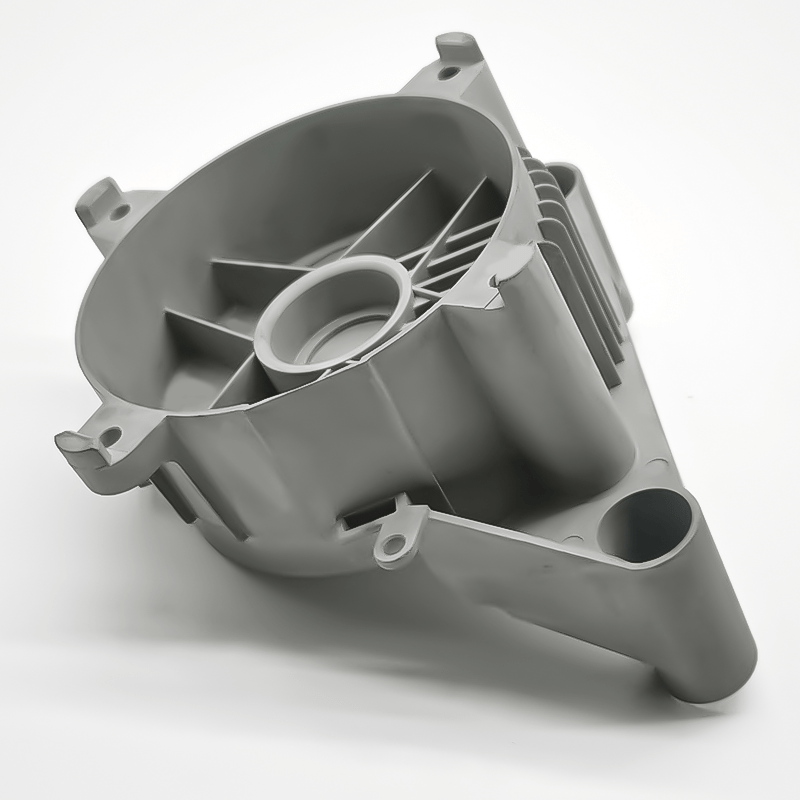

Products

Products