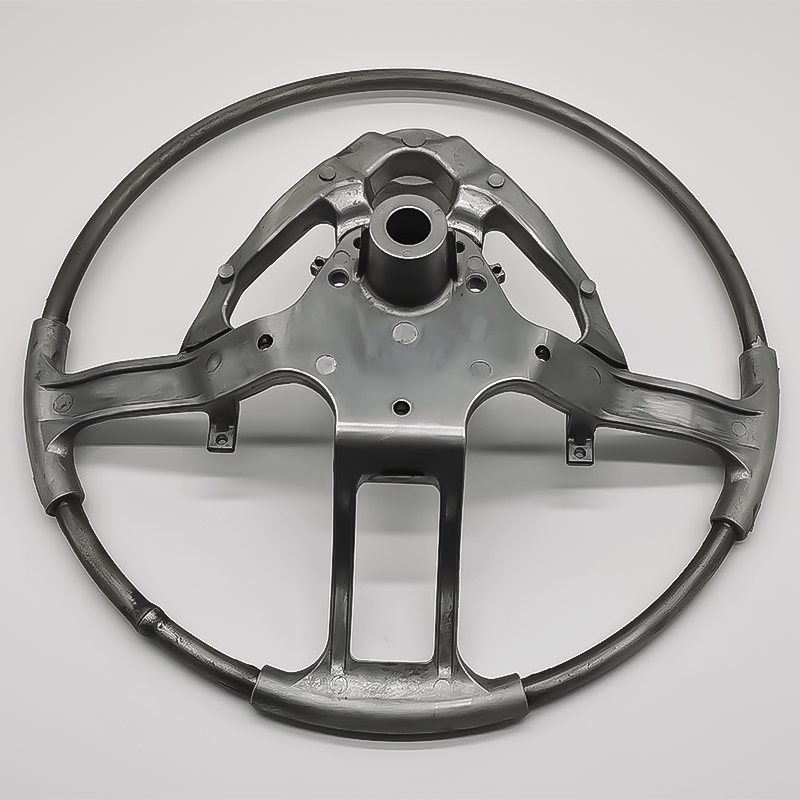

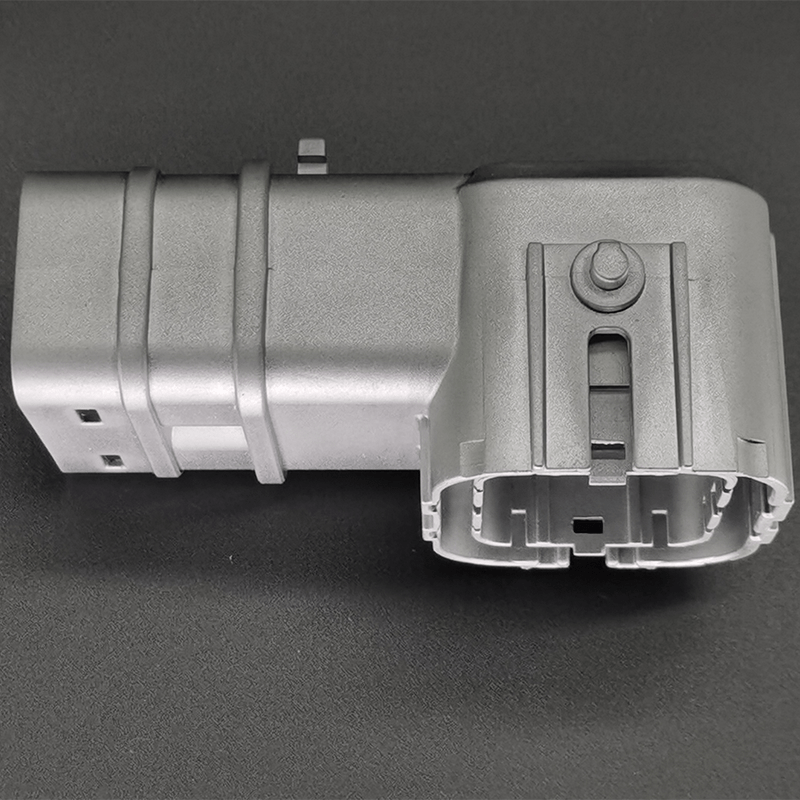

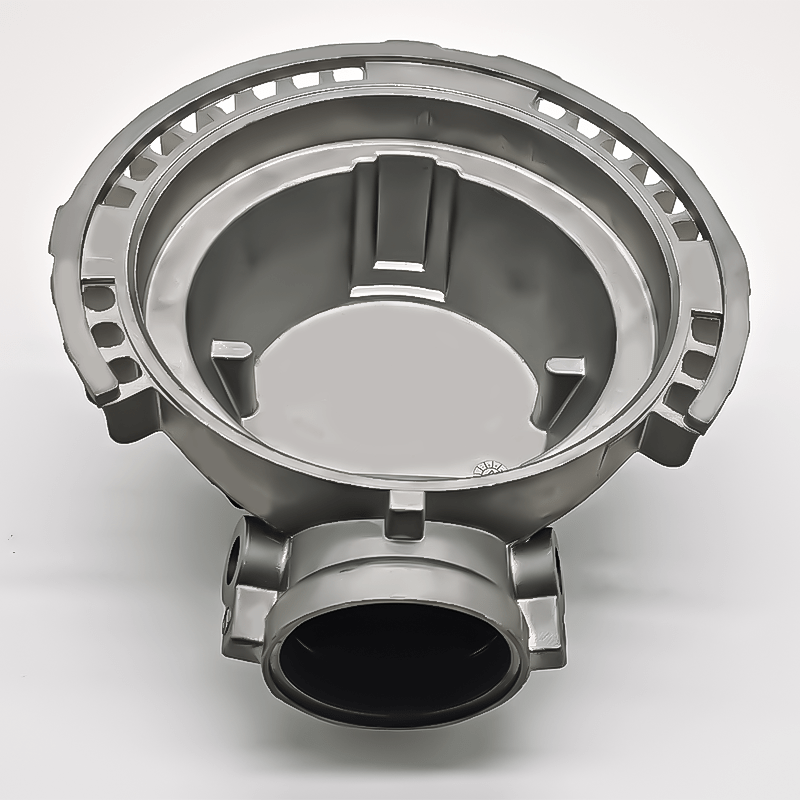

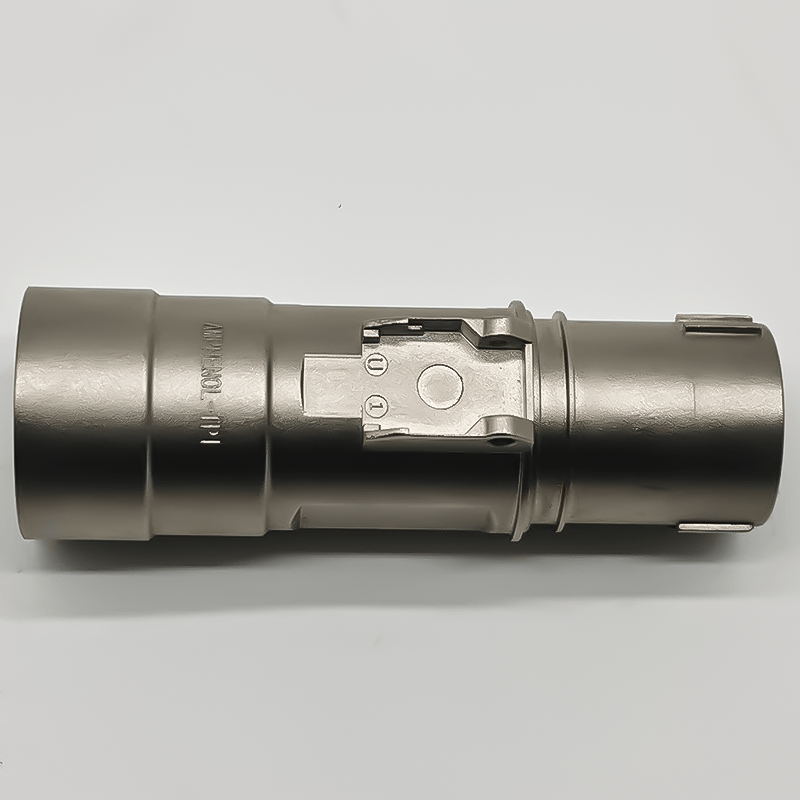

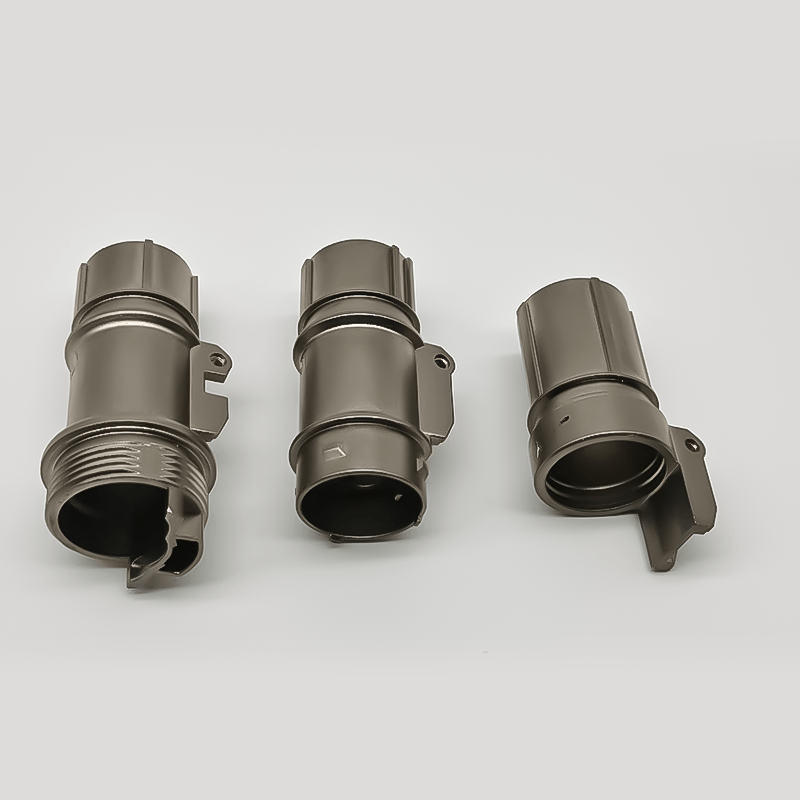

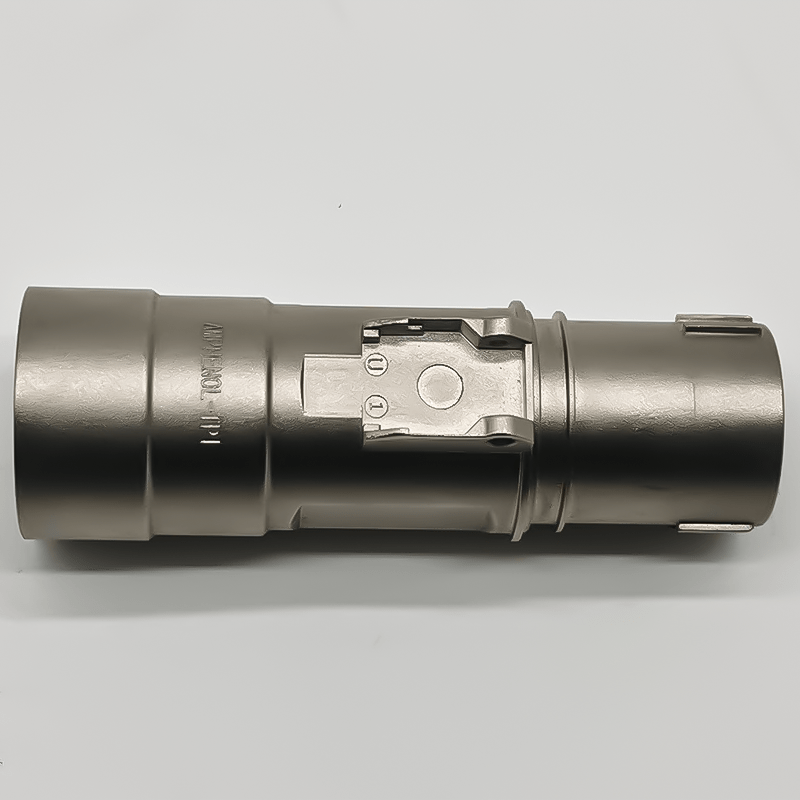

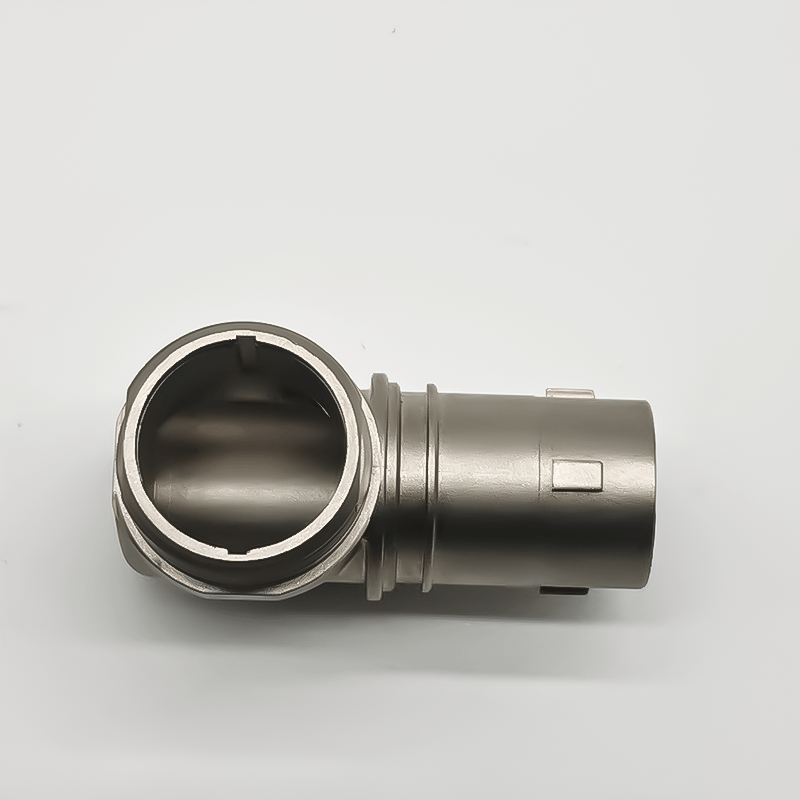

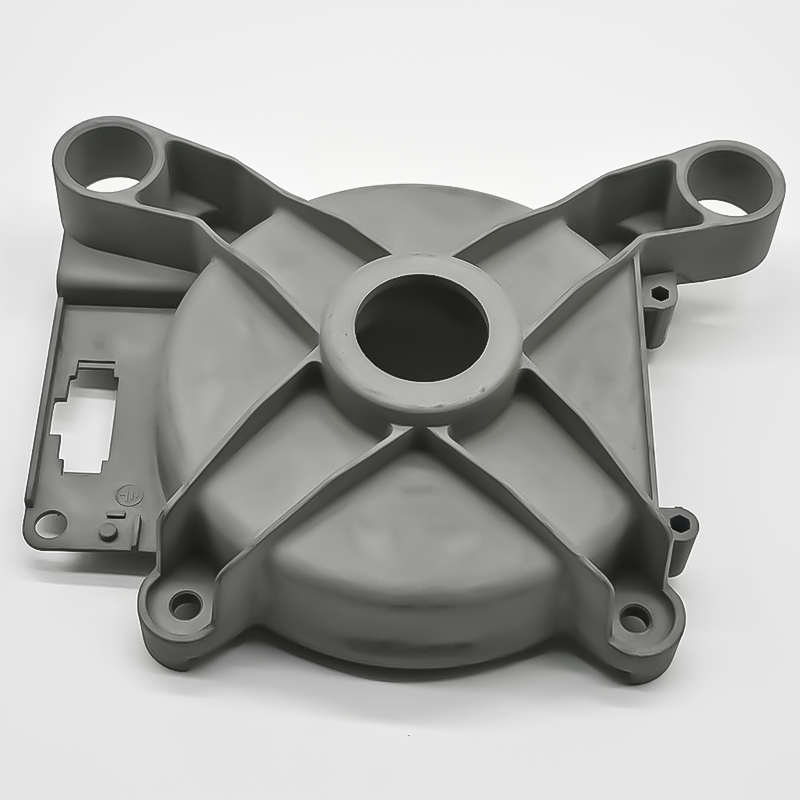

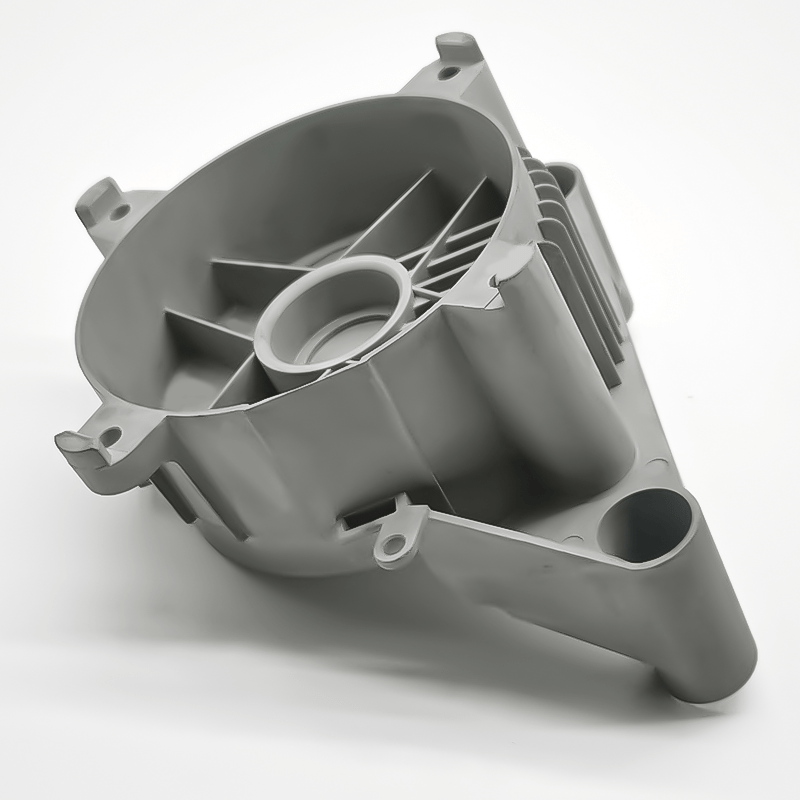

Connector shell zinc alloy die casting:

Connector shell zinc alloy die casting is an industrial accessory.

1.Connector shell zinc alloy die casting Product introduction:

Our company has more than 10 years of professional experience in customizing zinc and aluminum alloy connector shells. As a global OEM customization manufacturer, we provide professional die-casting solutions. It is now a supplier, manufacturer, and mass production of many Fortune 500 companies. And send samples, we can provide full size report and salt spray test report.

2. Connector shell zinc alloy die casting product specifications:

|

Mold specifications |

DME, HASCO, LKM, MISUMI, CUMSA or the requirements you provide |

| Die casting material |

commonly used materials : aluminium alloy:ADC12,A380,ADC1,A356 magnesium alloy :AM50,AM60,AZ91D zinc alloy:Z3,ZA-8,ZA-12,ZA-27 |

| Machine center | drilling machines and other mechanical spark machines, milling machines, punching machines, tapping machines,polishing machines, engraving machines, cranes, mold supporting machines, automatic polishing machines, die-casting machines, etc. |

| Mold manufacturing process |

1. DFM and mold design 2. Project Management Process 3. Mold manufacturing 4. Quality Control 5. Die Casting 6. Assembly and secondary operation 7. After-sales |

3. FQA:

Q: Are you a trading company or a manufacturer?

A:YuanZhang Mold is a Die casting mold manufacturer with 15 years of experience.

Q:How long is your delivery time?

A:It usually takes 25-30 days if the final design drawing is finalized. For complicated moulds, we will reply to you according to the specific situation.

Q:Do you provide samples? Is it free or extra?

A:Yes, we can provide samples for each test for free, but no shipping fee.

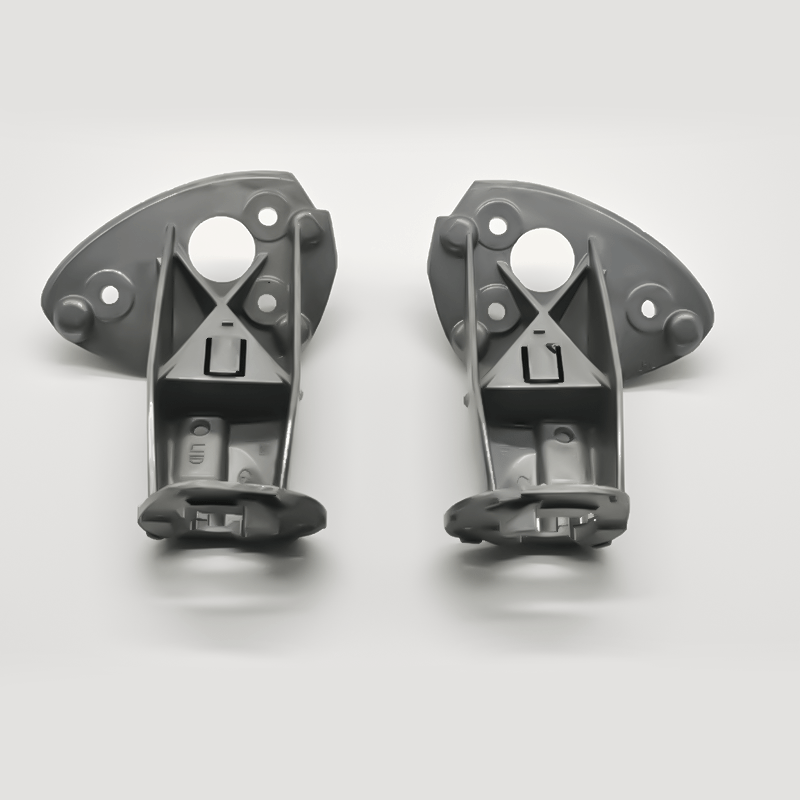

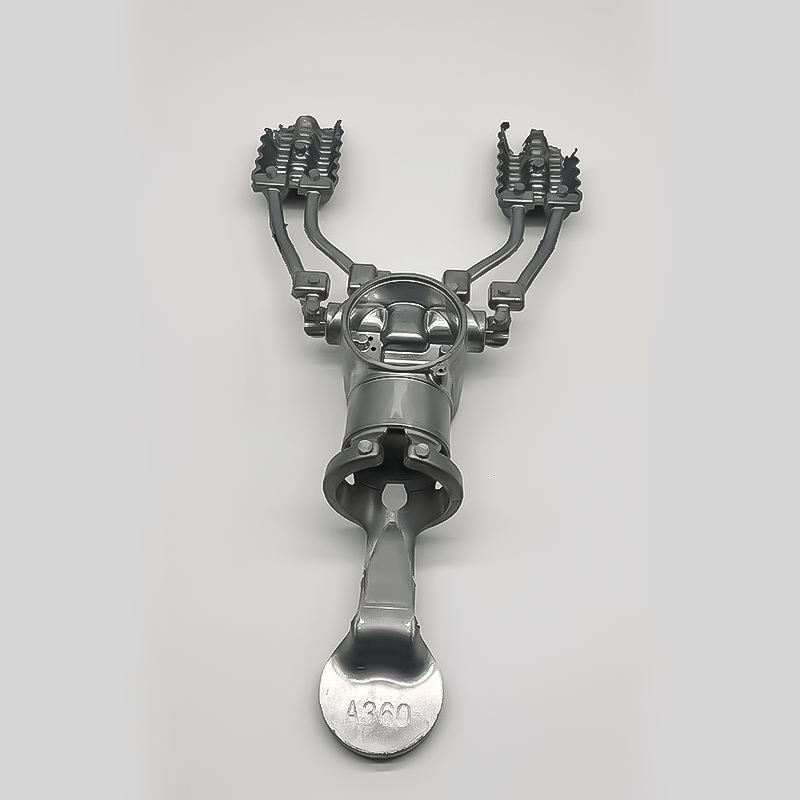

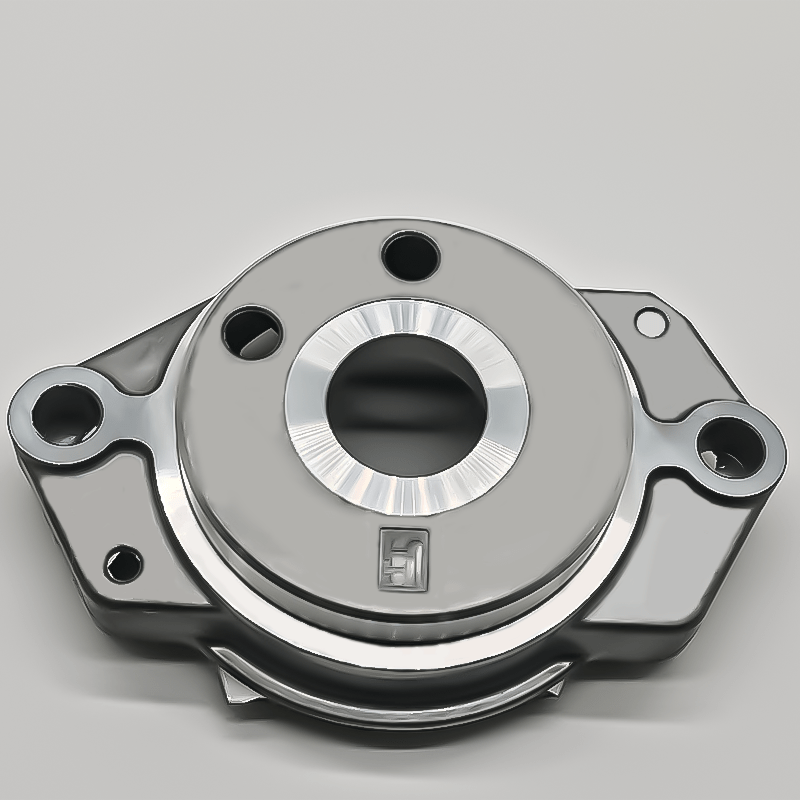

Products

Products